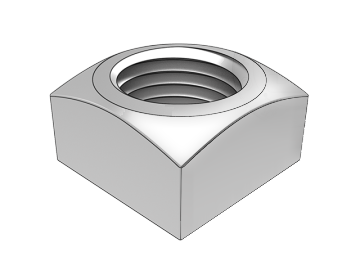

The design of square nuts for anti-loosening purposes requires careful consideration of several aspects to ensure they remain securely fastened under various operating conditions, preventing loosening:

Increasing Friction Force

Lock Washers: Install lock washers such as spring washers or locking discs between the square nut and the connected part. These washers increase the friction between the nut and the connected part, thereby preventing loosening. This method is cost-effective, easy to install, and suitable for frequently assembled/disassembled components.

Self-locking Nuts: Using self-locking nuts is also an effective anti-loosening measure. These nuts employ special designs (such as nylon inserts, necked-in features, or metal locking devices) to increase friction and achieve self-locking. They maintain a certain preload force after tightening, preventing loosening due to vibrations or impacts.

Mechanical Anti-loosening

Jam Nuts: Use two jam nuts tightened against each other. When these nuts are tightened, they interact and generate pressure between them, which prevents loosening. Even with variations in external loads, the pressure between jam nuts remains, effectively preventing loosening.

Wire Locking: Thread wires through holes in the square nut or bolt heads to interconnect them, creating mutual restraint. This method is highly reliable but may be more cumbersome during disassembly.

Chemical Anti-loosening

Thread Locking Adhesives: Apply thread locking adhesive on the threads of the square nut. Once the nut is tightened, the adhesive cures and fills the gaps between the threads, forming a hardened film. This film locks the threads, preventing the nut from loosening. This method is suitable for applications requiring permanent locking.

Consideration for Special Environments

High Temperature Environments: Select anti-loosening nuts that can withstand high temperatures or use high-temperature resistant lock washers or thread locking adhesives.

Low Temperature Environments: Standard nuts may become brittle or prone to cracking due to material characteristics in low temperature environments. Therefore, choose anti-loosening nuts resistant to low temperatures or implement appropriate insulation measures.

High Vibration Environments: Traditional nuts may loosen due to vibrations. In addition to mechanical and chemical anti-loosening measures mentioned above, consider using spring washers or nuts with higher preload force to enhance anti-loosening effectiveness.

High Humidity Environments: Standard nuts may lose their fastening performance due to corrosion in high humidity environments. Hence, select anti-loosening nuts with corrosion resistance, such as stainless steel or galvanized anti-loosening nuts.

Square nuts for anti-loosening design require comprehensive consideration of multiple factors, including increasing friction force, implementing mechanical anti-loosening measures, using chemical anti-loosening methods, and addressing special environmental considerations. These measures effectively enhance the anti-loosening performance of square nuts, ensuring they remain securely fastened under various operating conditions.

For exclusive deals and latest offers, sign up by entering your email address below.