The differences between round nuts with slotted designs versus smooth round nuts primarily relate to their intended applications, methods of installation, and functionality. Here’s a detailed comparison:

Slotted Round Nuts

Design:Slots or Grooves: Slotted round nuts have one or more slots or grooves cut into their outer surface. These slots can vary in number and depth.

Functionality:Locking Mechanism: The slots are often used to engage with locking mechanisms such as a cotter pin or a locking wire. This prevents the nut from loosening due to vibrations or dynamic loads.Adjustability: Slotted nuts allow for finer adjustments and can be precisely positioned and locked in place.

Installation:Tools: Typically installed using a spanner wrench or a similar tool that fits into the slots. This allows for a secure grip and precise tightening.Locking Devices: May require additional components like cotter pins or locking wires to secure them in place.

Applications:Mechanical and Automotive: Commonly used in automotive applications, machinery, and equipment where reliable locking is crucial.High Vibration Environments: Ideal for applications where the nut might be subject to movement or vibration.

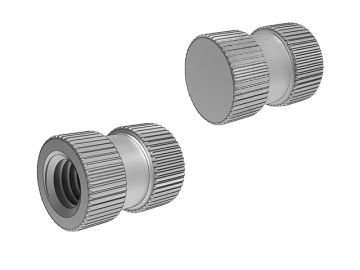

Smooth Round Nuts

Design:Smooth Outer Surface: These nuts have a smooth, cylindrical outer surface without any slots or grooves.

Functionality:Basic Fastening: Primarily used for general fastening purposes where additional locking mechanisms are not required.Simplicity: Offer a straightforward design for simple and easy installation.

Installation:Tools: Often installed using a standard wrench or socket that fits the internal thread. Some may require specialized tools if they are knurled or have unique internal features.Ease of Use: Generally easier to install and remove compared to slotted nuts, as no additional locking components are needed.

Applications:General Purpose: Used in a wide range of applications from light to moderate duty where locking mechanisms are not critical.Non-critical Applications: Suitable for use in applications where vibrations or dynamic loads are minimal.

Locking Mechanism: Slotted round nuts are designed to accommodate locking mechanisms to prevent loosening, while smooth round nuts do not have this feature.

Installation Tools: Slotted round nuts require specific tools that fit into the slots, while smooth round nuts can often be installed with standard wrenches or sockets.

Applications: Slotted round nuts are used in high-vibration or critical applications, whereas smooth round nuts are suitable for general-purpose fastening in less demanding environments.

By understanding these differences, you can select the appropriate type of round nut for your specific application needs.

For exclusive deals and latest offers, sign up by entering your email address below.