The flange on hex flange nuts affects the need for washers in an assembly in several important ways, often reducing or even eliminating the need for separate washers. Here’s how:

Load Distribution

1. Wider Surface Area: The flange provides a larger surface area compared to a standard hex nut, which helps distribute the load more evenly over the material being fastened. This can reduce the risk of damage to the surface and ensure a more secure fastening.

2. Preventing Surface Damage: By spreading the load, the flange helps prevent the nut from digging into the material, which can be especially beneficial when working with softer materials.

Vibration Resistance

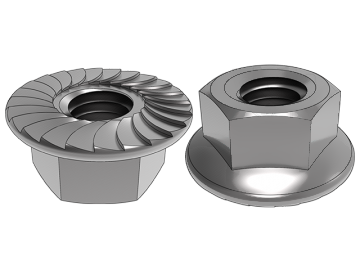

1. Improved Grip: The flange can provide a better grip on the mating surface, which helps resist loosening due to vibrations. This is particularly true for serrated flange nuts, which have a serrated surface that bites into the material to further prevent loosening.

2. Reduced Need for Lock Washers: Because the flange improves vibration resistance, the need for additional lock washers or other locking mechanisms is often reduced.

Simplified Assembly

1. Fewer Components: Using hex flange nuts can eliminate the need for separate flat washers, simplifying the assembly process. This can save time during installation and reduce the overall number of parts required.

2. Ease of Use: With the flange acting as an integrated washer, assembly becomes more straightforward as there’s no need to position a separate washer before tightening the nut.

Enhanced Security

1. Serrated Flanges: For serrated flange nuts, the serrations provide additional resistance to loosening. This feature can negate the need for spring washers or other locking devices in many applications.

2. Consistency: The integrated flange ensures consistent performance since it is always correctly positioned relative to the nut, whereas separate washers can sometimes be improperly aligned or forgotten during assembly.

Cost and Weight Considerations

1. Cost Savings: By eliminating the need for separate washers, the overall cost of the assembly can be reduced. This is particularly advantageous in large-scale manufacturing or construction projects where the savings can be significant.

2. Weight Reduction: In applications where weight is a critical factor, such as in aerospace or automotive industries, reducing the number of components by using flange nuts can contribute to overall weight savings.

Specific Applications

1. Soft Materials: In applications involving soft materials like plastics or softer metals, the flange provides a larger bearing surface, reducing the likelihood of material deformation or damage.

2. Corrosive Environments: Flange nuts can be coated or made from corrosion-resistant materials, providing enhanced protection without the need for additional washers that might corrode separately.

Load Distribution: The flange distributes the load more evenly, reducing surface damage and enhancing fastening security.

Vibration Resistance: The improved grip from the flange, especially in serrated versions, reduces the need for additional anti-vibration measures.

Simplified Assembly: Fewer components lead to easier and faster assembly processes.

Enhanced Security: Integrated features like serrations improve resistance to loosening.

Cost and Weight: Using flange nuts can reduce overall cost and weight by eliminating the need for separate washers.

Specific Applications: Ideal for soft materials and corrosive environments, providing protection and load distribution without additional components.

By understanding these benefits, you can see how hex flange nuts can streamline assembly processes and provide reliable performance in various applications.

For exclusive deals and latest offers, sign up by entering your email address below.